Welding works specialising in industrial applications

- Skilled welders with certificates of professional qualifications

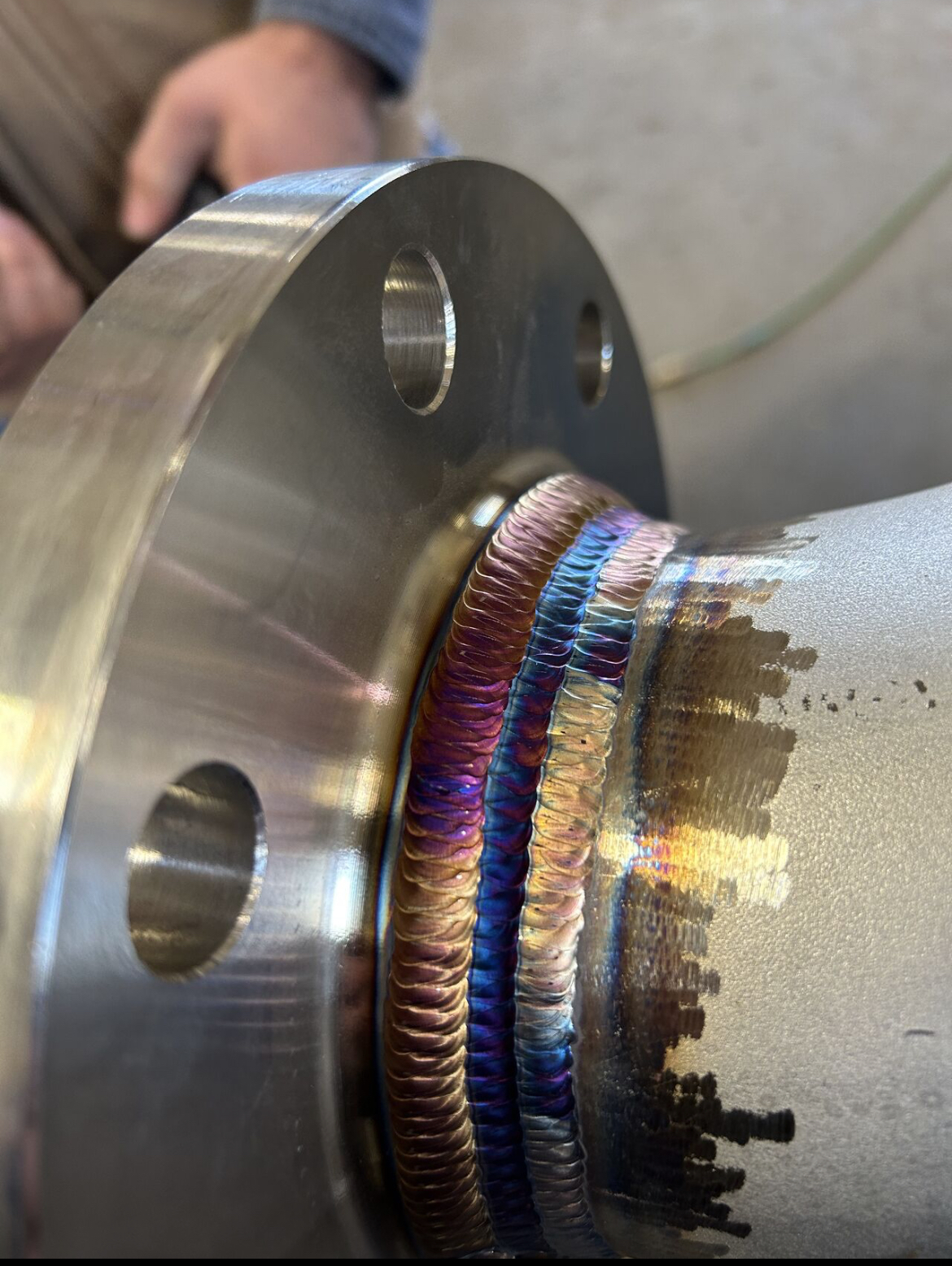

- Welding of steel and stainless material constructions for industrial use

- Welding of machinery units and additional technology constructions

- Welding and installation of pipe and duct systems

Methods we use in metal welding

- MMA/ Manual Metal Arc Welding – a universal method of metal arc welding

- MIG/ Manual Inert Gas – welding by a melting electrode in safety gas. The inert (or inactive) gas is usually argon, helium, or a mixture of the two. Metal arc welding in safety gas makes use of an electric arc between the electrode and the weldment.

- MAG/ Manual Active Gas – welding by a melting electrode in active gas. For this method the gas used is usually carbon dioxide reacting with the molten weld pool. Used for welding steel, stainless materials and aluminium alloys.

- TIG/ Tungsten Inert Gas – welding by a non-melting wolfram electrode A method based on the principle of electric arc between the wolfram electrode and the weldment in a safety atmosphere, using an inert gas – argon, helium, or their mixture. Advantages of this methods are easily controlled molten weld pool and the possibility to use the material of the weldment (an electrode) for welding, by which we can weld even very thin materials.

- Oxy-fuel welding, (oxyacetylene welding) This method uses the heat created by burning a mixture of flammable gas and oxygen. The material is welded together by melting of the weld area and of the additional materials. Acetylene is the flammable gas commonly used in this method. This method works for “welding & cutting “of steel constructions during their disposal.